Improving water safety is essential in any domestic, commercial or public building. From preventing contamination and Legionella growth to reducing the risk of scalding and system failure, water safety plays a vital role in protecting both users and infrastructure.

For installers, improving water safety is not just about meeting regulatory requirements, it is a core professional responsibility that spans system design, installation, commissioning and ongoing maintenance. A well-designed and properly maintained system supports compliance, improves long-term performance and, most importantly, safeguards public health.

This guide explores how installers can improve water safety by addressing system and user risks, navigating real-world installation challenges and specifying proven control measures such as thermostatic mixing valves, anti-Legionella valves and backflow prevention devices.

System safety: The technical foundation of improving water safety

System safety relates to the technical condition of an installation and how it is maintained during its lifecycle to improve water safety. Typically, this can include elements such as:

Water system design for safety and compliance

Equipping the system with the appropriate pipework layouts, the correct materials and components, and steering clear of dead legs.

Water safety control measures and pressure management

Using specific valves to ensure the safe temperature of hot and cold water, as well as avoiding dangerous over-pressurisation which can lead to system failure.

Correct maintenance practices for long-term water safety

Planning regular maintenance such as temperature monitoring, inspections of water outlets and storage tanks, cleaning and, of course, conducting any necessary repairs.

User safety: Protecting people from water-related risks

User safety is about the prevention of harm to people using the system. Extra precautions should be taken to keep vulnerable users, such as children, the elderly, or the disabled, safe. User safety considerations can be categorised into the following:

Preventing water contamination and bacterial growth

Reducing the risk of harmful bacteria or pollutants from entering or growing within the water system.

Reducing the risk of scalding at point of use

Minimising the risk of scalding, especially to children, older people and people with limited mobility.

Real-world challenges to improving water safety on site

Of course, improving water safety isn’t quite as simple as merely holding the knowledge. The realities of installing or maintaining a system, as with any job, can be challenging. Often, technical constraints, safety standards, the customer’s expectations (or budget!), and the building’s conditions can affect the difficulty of a project. Here, we outline some of the key challenges installers may come across during projects.

Overcoming legacy and poorly designed water systems

Installers will frequently inherit older or poorly designed systems which might include dead legs, unexpected and undocumented alterations, and hard-to-access pipe runs, all of which can make achieving optimum temperature control a tough ask. In domestic dwellings, lack of space in cupboards and limited room in risers or the plant rooms of multi-occupancy or commercial buildings can result in changes to intended pipe layouts or insulation. These can, in turn, affect the ease of future maintenance or water hygiene levels.

Managing legionella risks in domestic and commercial buildings

Water hygiene is a particularly important aspect of an installer’s work. Legionella bacteria, the cause of sometimes fatal Legionnaire’s Disease and Pontiac Fever, is commonly found in water and thrive in temperatures between 20°C and 45°C. For installers, preventing the growth of this harmful bacteria is critical. In fact, Part L of the Building Regulations mandates that installers actively take steps to prevent Legionella bacteria from forming in heating and water systems.

According to the HSE, hot water should be stored above 60°C, hot water distribution should be above 50°C, and cold water storage and distribution should be below 20°C. In addition to temperature, danger can also be presented when outlets are used irregularly, for example, within vacant buildings, hotels or seasonal properties. Installers must ensure sufficient steps are taken to safeguard against the risks posed by contaminated water.

Preventing scalding while maintaining safe system temperatures

Hot water distribution temperatures of 50°C and above present an obvious scald risk to users, therefore, it’s important to ensure temperatures are reduced before the point of delivery. For baths, showers and taps, temperatures should not exceed 44°C or, where vulnerable people are involved, 43°C when the system is running at the maximum design output. Further precautions must also be taken when fitting in healthcare establishments. For example, in NHS settings, this temperature becomes lower further still, and installers are required to ensure temperatures over 41°C are unachievable.

Limiting backflow to protect water quality

Backflow is the reversal of the water flow’s normal direction and is caused by changes in system pressure. Able to occur within any plumbing system, backflow can contaminate water and introduce harmful pathogens or toxic chemicals into the water supply, including E. coli, salmonella, pesticides and fertilisers. The Water Supply (Water Fittings) Regulations 1999 mandate that all water systems must contain adequate devices for backflow prevention.

How installers can improve water safety in practice

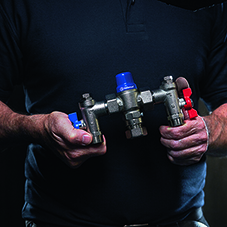

The efficient distribution of safe water can be managed in several ways; however, improving water safety can be achieved through the installation of purpose-built valves and fittings. We summarise these below to help installers achieve optimum water safety during installation and maintenance.

Using anti-legionella valves to reduce water stagnation

As suggested by its name, an anti-Legionella valve prevents Legionella bacteria from cultivating within plumbing systems. This is achieved by keeping water flowing through a standard single connection to an expansion vessel by redirecting a part of the flow into the vessel and regularly replacing the water inside.

Where space is at a premium, anti-Legionella valves can be used as an alternative to fitting a flow-through expansion vessel which can often be bulky and difficult to install in retrofit projects. To improve water safety and ensure the risk of water stagnation is at its lowest, the valve functions properly and is compliant with regulations, it’s always recommended to use WRAS certified anti-legionella valves.

Here are the three simple steps for installing anti-legionella valves:

Install directly between the cold feed and expansion vessel via the tee and vessel connection.

Insert the paddle retaining tube into the vessel connection by squeezing the tube together and pushing it into the vessel connection before letting it spring back into place.

Screw the Anti-Legionella valve onto the expansion vessel and tighten with a spanner.

For more detailed information on how to install anti-legionella valves, view our handy guide.

Thermostatic Mixing Valves (TMVs) for scald prevention

To reduce the risk of scalding and comply with HSE guidelines, installers should understand the importance of Thermostatic Mixing Valves (TMVs). While only legally required on baths in residential dwellings as well as educational or healthcare settings, TMVs can be installed ahead of every outlet where scalding may pose a risk to end-user safety.

To install a TMV, follow the steps below:

Specify the correct TMV type. TMV2s are used for domestic, commercial and public buildings such as schools and offices. TMV3s should be used for high-risk healthcare and social care environments.

The TMV should be installed as close as possible to the outlet it serves. This minimises lengths of warm pipework that prevent Legionella bacteria growth.

Access must be considered, with the TMV installed in a location that is easily accessible for future testing and maintenance.

Fit an isolation valve on both hot and cold supplies leading to the TMV. In addition to safe isolation, this again allows for future maintenance.

Single and double check valves for backflow prevention

Single check valves effectively prevent backflow risk by enabling water to flow in one direction only and should be used to prevent backflow in environments rated as a level 1 or 2 contamination risk. For a level 3 contamination risk and above, installers should use a double check valve. A double check valve provides additional reassurance through a backup valve if the other fails.

To install single or double check valves:

Ensure the valve is fitted in the correct direction using the arrow that is marked on the device. This indicates the direction of flow.

The valve should be accessible for future maintenance and not embedded in walls or concrete floors without an access panel.

Precautions must be taken for valves installed near external walls due to the risk of freezing.

Reduced Pressure Zone (RPZ) Valves for high-risk applications

Reduced Pressure Zone Valves, or RPZs, improve water safety through backflow by creating a physical barrier between the contaminated water source and the clean water supply. Typically used in settings rated Fluid Category 4 and above, the RPZ valve diverts back-fed water to a waste pipe during pressure drops or back siphonage, safeguarding the primary supply.

It’s important to note that RPZ valves must only be fitted by competent persons but here are a few important considerations ahead of installation:

Notify the local water company at least 10 days prior to starting installation works.

Prepare the location by installing isolating valves and a strainer upstream and downstream.

Fit the RPZ horizontally with adequate space for testing.

Mount the valve securely and connect to the incoming water line, making sure the relief valve discharges to a safe, visible place (usually a drain with an air gap) to prevent contaminants from entering if the relief valve opens.

Commission the valve through a WRAS/WTI Approved RPZ Tester and submit a certificate to the relevant water company.

Conclusion: The installer’s role in improving water safety

Improving water safety and keeping water systems free from harmful risks should always be a top priority for installers. In domestic, commercial, and community settings, taking the right precautions is essential to protect public health and safety. Failure to do so can result in illness, injury and even death.

Whether installing new systems, conducting retrofit works or performing routine maintenance, it’s crucial for installers to rely on high-quality products designed for longevity, safety and efficiency.

RWC’s family of brands, which includes Reliance Valves, JG Speedfit and SharkBite, brings together a range of precision-engineered solutions that make plumbing and heating installations safer and more sustainable.

With over 70 years’ experience, Reliance Valves, has helped thousands of installers carry out their vital role in creating safe and comfortable buildings. Discover the full range of Reliance Valves products here and work with confidence in the knowledge that your installations are safeguarding water systems for years to come.

Learn more

The installer’s guide to improving water safety in domestic and commercial buildings

| T | (01895) 425333 |

|---|---|

| E | Info@RWC.com |

| W | Visit RWC – Reliance Worldwide Corporation's website |

| Horton Road, West Drayton, Middlesex, UB7 8JL |

(002)-comp104848.png)