Service stations are notorious areas for high intensity traffic, where vehicles brake and accelerate, and where there is also a high concentration of hydrocarbons on the ground: petrol, diesel, lubricating oils.

This is the main reason why CNG Fuels Ltd has specified ULMA Civil F400K and F300K models in Fuel Stations in Birmingham and Knowsley.

CNG Fuels develops, owns, and operates CNG Refuelling infrastructure and sources 100% Renewable Biomethane or Bio-CNG for its stations.

The company is the UK’s leading supplier of Bio-CNG (compressed natural gas), the lowest carbon, most cost-effective alternative to diesel for HGVs.

CNG Fuels already supply 2,000 vehicles a day from its five public access refuelling stations, and a sixth station at Knowsley, near Liverpool, where ULMA drainage channels are being installed, which will be open in January 2021. Its newest station, close to the M6 at Erdington, east of Birmingham, can refuel up to 500 HGVs a day.

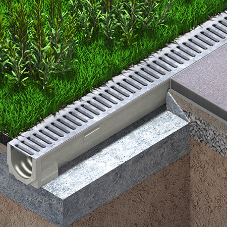

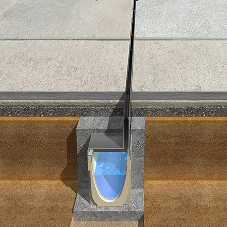

ULMA polymer concrete channels, highly resistant from exposure to chemical products makes them an ideal solution for installation in Gas Stations.

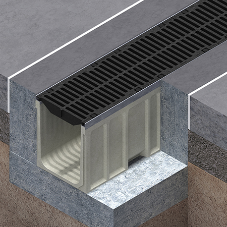

Civil F channels are also designed for heavy traffic areas and especially for sections where the grating is subject to large axial forces due to the manoeuvring and braking of vehicles. The channels are reinforced with galvanized steel profiles at the sides.

The gratings installed can withstand load classes of up to F900, ideal for areas with heavy traffic. In addition, their safety is assured with 8 attachment points per linear metre.

The Civil F system also makes it possible to incorporate a continuous 2.5% slope.

Why choose ULMA?

• Polymer concrete is one of the most resistant materials against chemicals.

• CivilF channels are especially designed for heavy traffic areas.

• FNX400FTFM Gratings are up to F900 load class and 8 attachment points per linear metre.

• ULMA study each project to guarantee the best solution, their technical and sales team will always be ready to help you.

View Civil Drainage Channels D400 E600-F900 Product Entry

-file111646.jpg)

-file111647.jpg)

-file111648.jpg)