One of the biggest challenges that faces multi-storey residential construction is the prevention of water ingress on flat roofs, terraces, and balconies. Every terrace or balcony will need a balustrade with face fixings that connect the balustrade back to the timber, steel or concrete primary structure.

In this article, BA Systems will explore the issues around waterproofing detailing their fixing bracket technology.

• Balustrade Fixing Penetrations on Roofs

The connection penetrates the water proofing membrane and the interface between the membrane and the steel connection is vulnerable to water ingress. According to insurance statistics, the highest number of waterproofing failures are found in balconies and terraces with disastrous and long-lasting consequences.

This can often become a frustrating dispute over long periods of time with a number of different sub-contractors or main contractors not willing to take responsibility for poor workmanship or mis management of that interface.

• Typical ceiling damage caused by water ingress

Many balconies and terraces are constructed with minimal fall which can result in water pooling in certain areas, and this can often occur in the region of a membrane penetration.

In most cases the recommendations are that the membrane must have a 150mm upstand around the penetration to prevent water ingress in the case of excessive pooling or blockages at the drains.

This can often present a conflict between the waterproof membrane manufacturers requirements and the architects design intent.

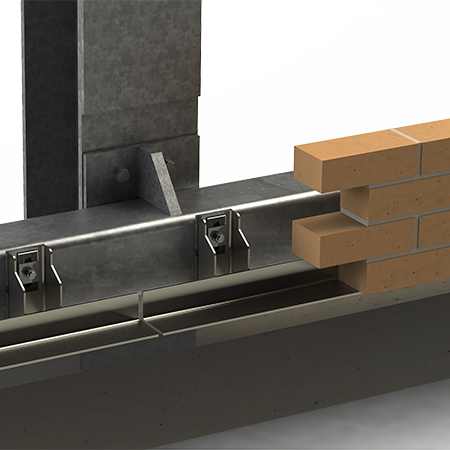

This is especially the case where a continuous base channel is fitted to receive a frameless glass balustrade such as the B40 frameless glass system.

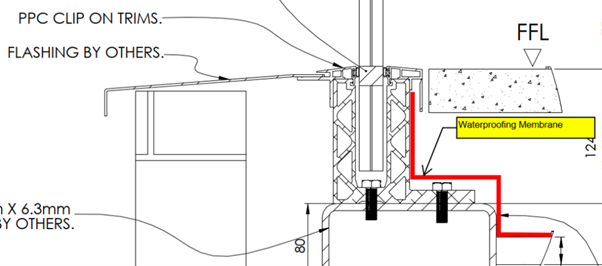

In this instance, the architects design intent is to keep as much of the base channel below finished floor level but there is very little build up between the structural floor level and the finished floor level.

This means that there is often not enough height to get the 150mm upstand around the penetration without the upstand and waterproof membrane becoming visible above the finished floor level.

In the case of a continuous base channel for a frameless glass balustrade to a balcony or terrace the design often shows the membrane lapped up against the inside of the base channel as shown in the detail below.

This, however, assumes that the channel itself is watertight and the channel effectively becomes part of the water proofing strategy. What can happen in these instances is that water ingress can occur at joints or penetrations in the channel or at the ends of the base channel.

Water then finds its own way through the insulation layers and eventually penetrates the residence or building causing damp, mould or worse still, constant dripping water.

• Introducing DriMax

1. Seamless waterproofing, interfacing with other trades to ensure the most reliable solution

2. Non-combustible solution, compliant with BS EN 13501-1:2007+A1:2009

3. Endorsed by waterproofing manufacturers

The DriMax concept is designed to coordinate with a number of different single ply membrane systems systems without compromising the structural integrity of the balustrade.

The key to an effective water proofing strategy is early engagement and early design and coordination between the DriMax system and the membrane manufacturers to ensure that the concept is endorsed by the manufacturer and the warranties are not compromised.

The system lifts the continuous base channel outside of the whole waterproofing strategy and allows water to dissipate underneath the channel but effectively seals the penetration through the single ply membrane.

The system can easily be adapted to a number of different fixing situations or heights between finished floor levels and structural levels and is bespoke designed to each application.

Waterproofing Membranes for Balustrades: Introducing DriMax

| T | (01603) 722330 |

|---|---|

| F | (01603) 722777 |

| E | sales@firma.co.uk |

| W | Visit FIRMA's website |

| 22 Bidwell Road, Rackheath Ind Est, Norwich, Norfolk, NR13 6PT |

-comp212644.jpg)