Standing out from the crowd and making an impact is considered a good thing in many contexts, but when it comes to rendering, the opposite is true. If you don't know the builders have used Renderplas PVC render beads, that's probably because they are doing their job.

In the world of building aesthetics, the most important and impactful elements are often the ones you never notice. While dramatic architectural features grab headlines, it's the subtle details that create truly polished facades, and render beads are a perfect example. The best render beads should seamlessly disappear into the building's exterior, creating clean lines without drawing any unwanted attention.

For Renderplas, a lack of visibility isn't a sign of failure – it's proof that it’s doing everything right.

The art of going unnoticed

Not all render beads are quite so good at fading into the background.

Traditional steel render beads, for example, have a habit of making themselves known, and not in a good way. Rust-stained bleeding down building facades creates unsightly reddish-brown streaks that immediately catch the eye for all the wrong reasons. These prominent blemishes not only ruin the intended aesthetic but also signal premature deterioration and poor material choices.

Renderplas PVC render beads take the opposite approach. By eliminating the chance for the beads to corrode entirely, they maintain their intended appearance throughout the building's lifespan.

No rust means no staining, no discolouration, and no unwanted visual interruptions that break up the clean lines of a well-designed facade.

Designed to disappear

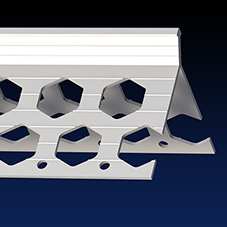

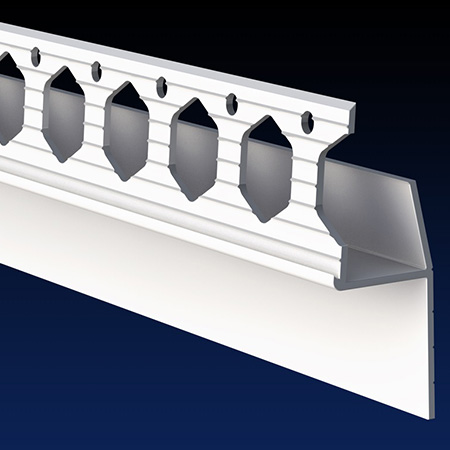

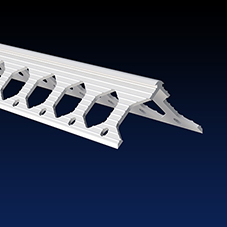

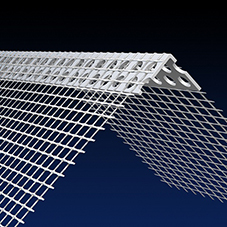

Neatly blending into the building facade requires careful attention to both form and function. Renderplas PVC render beads are specifically engineered with a very narrow arris – the sharp edge where the bead meets the render. This minimal profile ensures the bead doesn't create noticeable voids or raised edges that could compromise the smooth finish.

The range extends across different render thicknesses, ensuring architects and contractors can specify the perfect profile for their particular application. Whether working with thin renders on externally insulated developments or thicker traditional brick and block applications, the right profile maintains that seamless integration.

A key part of this ability to blend in lies in the range of colours available. Renderplas offers nine natural colour options designed to match popular render systems from leading manufacturers. In addition, UV stabilisation technology ensures these colours maintain their integrity over decades. This means that while inferior materials might fade unevenly, creating patchy appearances that draw attention, Renderplas PVC render beads age uniformly and as slowly as possible.

Strength without show

Behind this understated appearance lies serious engineering strength. PVC's inherent flexibility helps prevent cracking around vulnerable areas, while polymer modifiers enhance impact protection. The material's resistance to moisture, salt, and chemical reactions means it won't compromise over time, maintaining both structural integrity and aesthetic appeal.

Renderplas guarantees its BBA-certified PVC beads for the full service life of the render, typically at least 25 years, which beats many metal alternatives. They won’t need repainting, patching, or replacing, and they often survive re-rendering jobs without being cut out.

The professional choice

For builders and developers, choosing materials that blend seamlessly demonstrates attention to quality and long-term thinking. When Renderplas PVC render beads are properly specified and installed, they become part of the background – allowing the building's design to take centre stage while quietly ensuring structural performance for decades to come.

Sometimes the best compliment a building element can receive is going completely unnoticed.

Read more Renderplas articles on the DMA News Portal

Why the best beading blends in

| T | 01299 888333 |

|---|---|

| F | 01299 888234 |

| E | enquiry@renderplas.co.uk |

| W | Visit Renderplas's website |

| Number 2, 70-72 High Street, Bewdley, DY12 2DJ |

Products by this Company

-file166712.jpg)

-file166714.jpg)

-file166715.jpg)