The release of the Draft Building Safety Bill is set to make the biggest changes to safety in 40 years by improving regulations to aid the construction industry. The new bill will help achieve a clearer and more consistent system that ensures individuals’ safety remains the priority, not only throughout the initial construction process, but the entire lifecycle of the building.

Here Mick Hill, Technical Specifications Manager at Profab Access, explores the importance of providing a ‘Golden Thread’ of building information by specifying components, including bi-directionally fire tested riser doors, that offer the highest standards in compliance and performance.

The initial Hackitt Report revealed significant concerns surrounding the quality assurance of fire doors, particularly with regard to the certification of these components and the lack of available corresponding building information.

Just last year, an investigation from Inside Housing into the replacement of faulty fire doors by councils across the UK found that across 98 councils, around 10% (approximately 33,000 fire doors) were unlikely to satisfy the 30 minute standard.

While research such as this demonstrates just how far the construction industry still has to go with regard to fire safety, the release of the Draft Building Safety Bill, along with the initial Hackitt Report and subsequent amendments to Building Regulations Approved Document B (Fire Safety), marks the first significant step in helping the sector to achieve a safer and more transparent environment for individuals to live and work within.

The ongoing maintenance of these buildings and the components installed throughout them is also a significant factor, which will be addressed within the associated consultation of the Draft Building Safety Bill, which aims to strengthen fire safety in all regulated buildings of all heights throughout England.

While the actual application of the revised regulations and guidance may take a while to come into force, it marks the start of the implementation of the Building a Safer Future consultation. This includes increased accountabilities during the design and development stage, as well as the position of an accountable person for the ongoing management of multiple occupancy dwellings.

In order to successfully meet the requirements outlined within the new guidance, professionals should take a proactive approach to the specification of passive fire safety components by selecting building products that supersede current industry standards and are supported by certified performance test credentials.

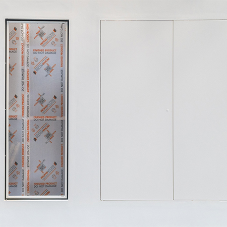

This includes having a clear understanding of the fire testing each product has undergone and the legislations it complies with. With specific regard to steel riser doors, architects should specify solutions that have been fire tested to BS EN 1634-1:2014+A1:2018 or BS 476 part 22, as outlined in Annex C of Approved Document B Volume 2.

Where designated, the doors should also comply with BS 476-31.1 for smoke tests, BS8214 for the installation for fire doorsets and should be specified and installed in accordance with BS 9999:2017 for the Code of practice for fire safety in the design, management and use of buildings.

As the release of the Draft Building Safety Bill looks to ensure buildings are fit for purpose throughout their entire lifecycle, architects should specify solutions that not only adhere to current regulations, but successfully futureproof a building. This ensures compliance with upcoming regulations, whilst simultaneously meeting the specific requirements of each individual working or living within that building.

This also ties directly into the ‘golden thread’ of information outlined within the Hackitt Report, with test certifications providing architects with the necessary information to not only provide a transparent trail of due diligence, but successfully communicate key information about a building and the components utilised throughout its construction to all relevant individuals.

With regard to riser doors in particular, architects should look to specify bi-directionally fire tested models as the certifications successfully document the prevention of the spread of fire throughout a multi-storey building, regardless of which direction/location the fire starts in. This also evidences compliance with the test exposure from both sides as required by ADB, in addition to the asymmetrical clauses of BS EN 1634-1.

Because the riser doors are physically tested in both directions, it provides the confidence the integrity of the door will adequately withstand exposure to fire and smoke from both directions for the stated time period, eliminating the possibility for fire to enter or exit the riser shaft.

Specifying products including fire doors that have been third party tested by a certified provider will also further enhance the ‘golden thread’ of information, as it provides a clear trail of evidence that ensures the passive fire product complies with all current legislations, whilst also going above and beyond in terms of best practice.

The certification of fire doors by an accredited third party, rather than being tested by the manufacturer themselves, also provides architects and their clients with the highest standards of confidence and assurance the doors will not fail in the event of a fire. This is supported by comprehensive test documentation that physically proves the suitability and performance of the doors, not only for the outlined duration, but throughout every stage of the manufacturing process.

This is because third party testers are involved throughout the entire construction process to ensure manufacturers implement appropriate measures that maintain manufacturing consistency and that the products tested are a true representative of production. This subsequently provides architects and their clients with the reassurance that each riser door specified is of the highest quality and offers unrivalled levels of performance.

While Bi-directional fire testing isn’t a current industry requirement, professionals can face unlimited fines if the products specified fail to meet the standards legally required. To avoid this, architects must demonstrate all reasonable steps have been taken during the specification process by choosing certified products that have comprehensive evidence.

This includes the documentation produced by third party fire bi-directional testing, which not only ensures both exposure faces where the ADB and associated standards require it, but reflects the principles of the Draft Building Safety Bill to help ensure a building will deliver, and continue to deliver, the highest standards in fire safety.

Ensuring safety through sufficient fire specification [BLOG]

| T | 01827 718222 |

|---|---|

| 01827 719051 Tech Dept. | |

| E | sales@profabaccess.com |

| W | Visit Profab Access's website |

| Riversdale House, C-D Riversdale Road, Carlyon Road Industrial Estate, Atherstone, Warwickshire, CV9 1FA |