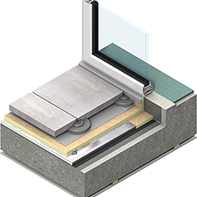

A new white paper has highlighted that tapered roof insulation systems, which combine flat roof insulation and drainage in a single product, can achieve considerable savings when compared with other common methods for creating a fall on a flat roof.

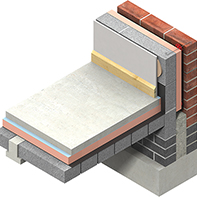

The report shows the tapered insulation systems require no drying time, can be as little as around 3% the weight of screed to fall systems and deliver cost savings of as much as £58 per m2 (43%) on the roof build-up above the deck.

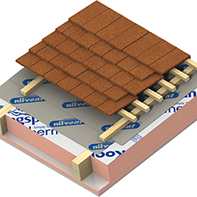

The Flat Roof Drainage white paper from Kingspan Insulation examines three commonly used methods of achieving a fall on a warm deck flat roof:

• screed laid to falls;

• timber firrings under a plywood deck; and

• tapered roof insulation (specifically Kingspan Thermataper Systems)

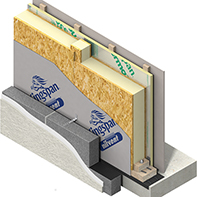

It features a comparative cost analysis from Currie & Brown, looking at the three approaches across four new build non-residential buildings with concrete decks. These included a hospital extension and office blocks, with roof areas of between 192 m2 and 3,073 m2. All of the constructions use Kingspan Therma range insulation and are designed to achieve identical U-values of 0.16 W/m2K.

The results showed that the Kingspan Thermataper Systems provided the most cost-effective option across all four case studies. The system provided savings of £43 - 58 per m2 (up to 43%) on the roof build-up above deck when compared with screed to falls and £15 - 32 per m2 (up to 23%) when compared with the timber firrings. The analysis concluded that Kingspan Thermataper Systems would also provide cost savings on timber and metal deck roofs when compared with timber firings.

The white paper also highlights that a standard cement: sand screed dries at approximately one month per 25 mm thickness. This means that the drying time can be as much as 195 days or more on larger surfaces – greatly extending project timescales. Whilst this can be reduced with a quick-drying screed, this will raise system costs by between 40-50%.

Weight is also identified as an issue, with standard cement: sand screed weighing around 2000 kg/m3. When applied to the 3,073 m2 case study roof this led to a total above deck system weight of 1,005,000 kg, compared with just 23,000 kg for the Kingspan Thermataper System. This added weight will have clear structural implications for the building foundations and frame along with additional costs beyond those highlighted in the Currie & Brown analysis.

To read more about the research and the benefits tapered roof insulation can provide, download the Flat Roof Drainage white paper.

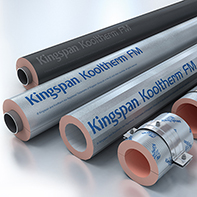

View Roof Insulation Product Entry