Sustainable Asphalt Solutions

Holcim Asphalt

Warm Mix Asphalt

Aggregate Industries have made the switch!

They are driving forward with the commitment towards Net Zero. Moving their asphalt production from hot mix to warm mix.

What is Warm Mix Asphalt (WMA)?

Mixed at temperatures 20°- 40°C lower than hot mix asphalt (HMA), warm mix asphalt provides a more sustainable solution for road applications.

All base and binder material is now produced as warm mix as standard. In addition Aggregate Industries has attained BBA certification for their SHW Clause 942 materials as a warm mix, and many of their performance asphalt products can also be manufactured as warm mix.

How does it work?

Through the use of additives and innovative technology, they’ve tested their range of asphalt products to ensure they still meet national specifications, including National Highways standard (SHW clause 908). Warm mix asphalt reduces CO2 emissions by using less fossil fuels and resources during the manufacturing process.

Environmental benefits of using warm mix asphalt, include:

- CARBON REDUCTION

- REDUCED PROJECT COSTS

- ENHANCED LIFE-EXPECTANCY

…WITH THE SAME HIGH QUALITY AND PERFORMANCE WHEN COMPARED TO HOT MIX

On site benefits:

- REDUCED NUISANCE FUMING

- MINIMAL ODOUR AND STEAM AT THE PROJECT SITE

- SAFER WORKING CONDITIONS AT BOTH THE PLANT AND SITE

________________________________________________________________________________________________________

Foamix®

Foamix® asphalt is a hybrid between Asphalt and Hydraulically Bound Material (HBM). Manufactured as a cold mix, it contains a high recycled content asphalt resulting in a low manufacturing carbon footprint. Manufactured to a high level of control and incorporates up to 92% recycled materials, reclaimed filler/additives, plus bitumen, cement and water.

Using their fleet of Sitebatch Technologies mobile mixing plants, Foamix offers a cost-effective, sustainable solution to their customers for the construction, repair and maintenance of new or existing pavements whilst maximising the use of locally sourced recycled materials. It is laid and compacted like normal asphalt, only cold, without the need for any specialist paver or labour.

With the ability to encapsulate tar-bound RAP for safe reuse in the local road network, Foamix offers their clients a more sustainable solution that eliminates costly disposal charges associated with hazardous waste at licensed tips.

Features & Benefits

- CAN USE UP TO 95% RECYCLED OR RECLAIMED PRODUCTS IN THE MIX DESIGN

- MATERIAL IS SUPPLIED AND LAID COLD, SO SAFE TO THE TOUCH

- CAN BE STORED IN ANY CONVENIENT LOCATION FOR EVERYDAY USE OR ‘OUT-OF-HOURS’ EMERGENCIES

- IF COVERED AND STORED ON GOOD, DRY GROUND STANDARD GRADE CAN BE HELD ON STOCK FOR UP TO ONE MONTH

- A SINGLE LAYER OF FOAMIX CAN REPLACE MULTIPLE LAYERS E.G. BASE AND BINDER COURSE

This allows for cost and time efficiency.

________________________________________________________________________________________________________

SuperLow-Carbon

The development of their SuperLow range, which supports their shared journey to reduce carbon in the industry, never stands still.

With the help of Shell Bitumen, Aggregate Industries has developed SuperLow-Carbon; the innovative next step on the carbon reduction journey.

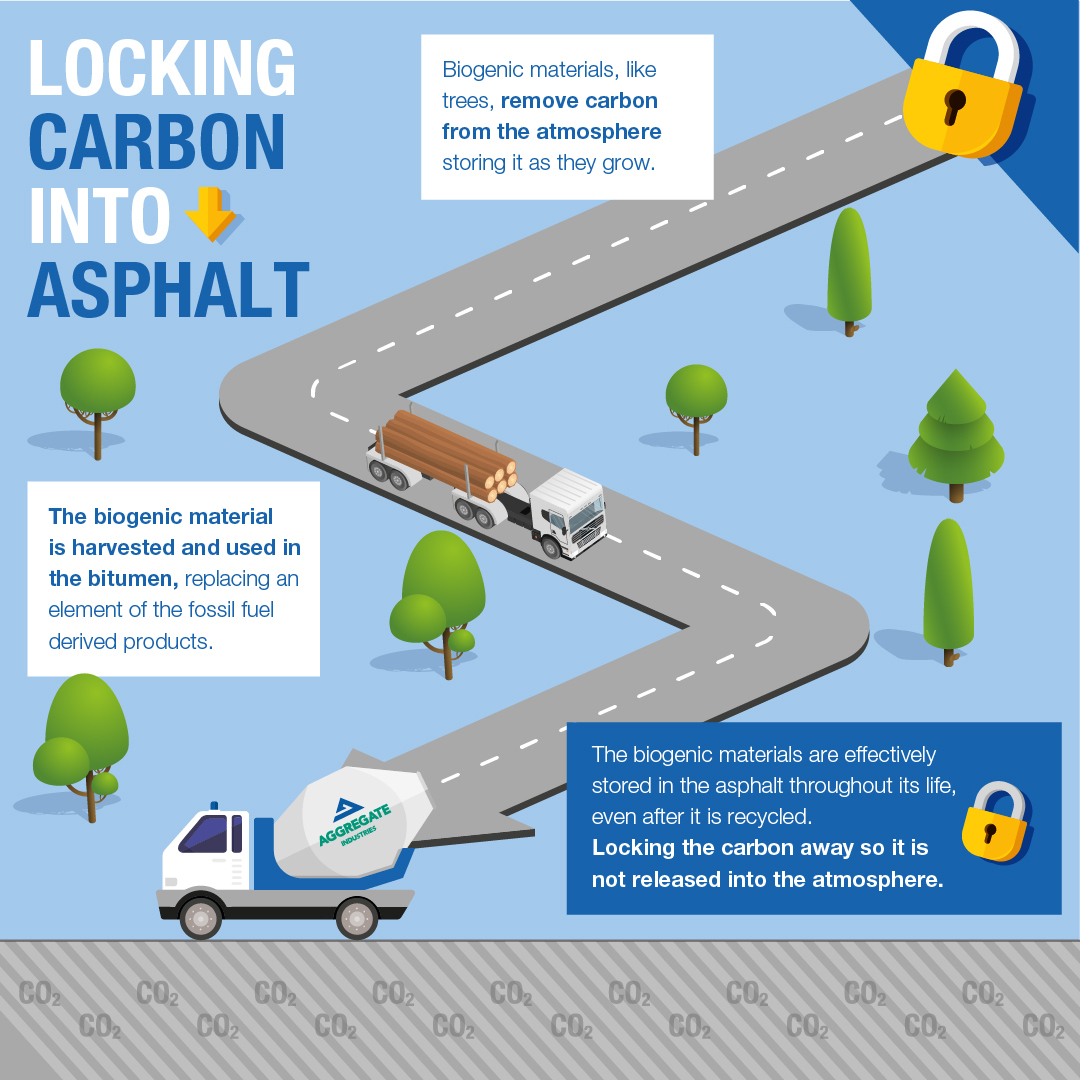

The evolution began by reducing the embodied carbon footprint of their asphalts: improving production processes, using alternative energy sources, and mixing at reduced temperatures. In SuperLow-Carbon, they have gone even further, including a biogenic material within the bitumen that effectively locks carbon within the asphalt rather than releasing it back into the atmosphere.

The use of these biogenic components in SuperLow-Carbon means that CO2 remains within the asphalt even when it is recycled, creating a carbon sink.

________________________________________________________________________________________________________

Contact the dedicated asphalt team for more information.

North: 01524 738887

Midlands: 01455 288222

South: 01373 451234

-file133597.jpg)

-file133601.jpg)