Throughout most of Europe, pipelines are traditionally pressure-tested using water. However, according to some experts, air pressure testing offers a more secure pressure testing method, reducing the risk of both Legionella and water damage, especially for large commercial new builds. Wavin’s new leading press-fit plumbing system Tigris K5 uses air testing with the world’s first acoustic leak alarm.

Don Elworthy is a Senior Contracts Manager at Panks Engineers Ltd in the UK. Panks engages in various projects: including large commercial new builds and residential one-off remodels and repairs. They specialise in building hospitals and schools, where hygiene and cleanliness reign supreme.

When specifying pressure testing methods, Don always requires air-pressure testing during construction.

“We section off about 50 metres of pipe at a time and test as construction progresses,” Don explains. “We do it this way for two main reasons. Firstly, we can avoid frozen or burst pipes in winter. And secondly, but most importantly, as it eliminates the risk of Legionella bacteria in the pipes.”

Reducing the risk of Legionella

Seven water corporations that regulate Legionella in the UK demand Legionella risk assessment reports for each new structure constructed in the nation. Don is fully responsible for these reports, and Legionella is always front of mind. Legionella bacteria may develop in pipes if they are not effectively dried after water-pressure testing.

Don believes, “When you pressure test with air, you can skip the time-consuming drying phase, but also be 100% assured that no Legionella bacteria have been introduced to the pipes during construction. This is particularly important in the hospitals and schools that we build.”

In order to speed up the construction process, some installers and contractors in the UK might overlook the risk of a leak. Don is unwilling to take that kind of risk.

“I insist we pressure-test religiously. Not only does this reduce our damage liability, but it’s also one of our most important selling points to new clients. They benefit from this extra level of security as they can be sure they will not experience a leak that can cause further damage to their asset.”

Reducing liability and damage costs

In the Netherlands, leakage is a vital topic for insurance companies. Each year, 60,000 insurance claims are filed due to water damage – a value of approximately 200 million euros. 25% of these damages are caused by drinking water installations.

Eric van der Blom, Sanitary Specialist at Techniek Nederland, the Dutch business association of technical service providers, installation companies and the technical retail trade. He is closely involved in drafting standards, practical guidelines and quality assuring systems for sanitary installations, including the pressure testing of drinking water installations.

“We’ve recently rewritten practical guidelines for pressure-testing drinking water installations. With large buildings, water-testing puts you at a big disadvantage because you have to flush the water through the pipelines every week of the build. This costs a lot of time and money.” Because air pressure testing is done incrementally it saves time overall. Each air pressure test takes minimum of 130 minutes, compared to only 20 minutes for each water test. However, when you add the preparation time of a water test (the time it takes to get all air out of the system) and the fact that the whole installation needs to be flushed once per week, water testing is more cumbersome and takes much longer.

“Our view is that pressure testing should be as convenient as possible so that installers and contractors will prioritise it, with the sound of a leak fitting, it is easier to find where repairs are required. That’s why we recommend air-pressure testing for larger installations,” says Eric. “In that way, we hope to reduce the annual insurance claims due to leaks.”

By removing a water source, installers can remove risk from the job site. Water damage is the second most frequent cause of loss during building projects and represents a large percentage of Construction All Risk (CAR) claims. Pressure testing with air means you can be 100% sure that leaks won’t destroy electrical installations, new flooring or fresh drywall. The work environment becomes safer as well.

Learn how to pressure test with Tigris K5 here.

Wavin Tigris K5 Press-fit System

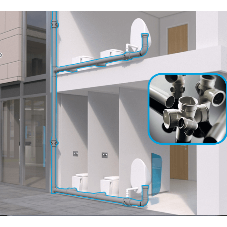

Wavin Tigris K5 press-fit system is a multilayer composite pipe (MLCP) for commercial projects. It is designed for ease of installation, performance and reliability and features an innovative Acoustic Leak Alarm, which detects leaks quickly and easily, as any non-pressed fitting will produce a loud whistling sound for easy localisation.

It also has a range of performance and installation features including:

• Optiflow, making it best in class in flow performance with up to 50% increased inner bore.

• Multi-jaw press connection - fittings can now also be pressed with common pressing profiles like U and Up, TH, H and B

• Easy pipe insertion without calibration

• In4Sure™ for proper pipe position that is visible 360°

• Pipe grip - pipe stays in position before pressing

• Clear visual leaking when the pipe is not pressed

• Reliable O-ring sealing, tested beyond market standards

Discover Wavin’s New MLCP Tigris K5 here.

The Benefits of Air-pressure testing – Wavin Tigris K5

| T | 0844 856 5165 |

|---|---|

| E | online.enquiry@wavin.com |

| W | Visit Wavin's website |

| Wavin Limited, Parsonage Way, Chippenham, SN15 5PN |

Products by this Company