1000 Aztec West stands as a testament to what is possible with a well-considered retrofit. Working with Commercial Estates Group (Development Manager), the project team has transformed the previously tired office building into a truly modern headquarters building that achieves net zero operational carbon whilst also retaining the original structural frame to limit its embodied carbon impact.

Location: Bristol, England

Sector: Commercial Office

Development Manager: Commercial Estates Group

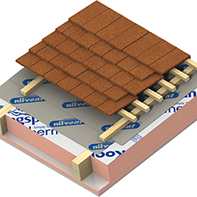

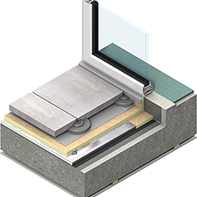

Products: OPTIM-R E Inverted Roofing System

Application: Roof

The Project

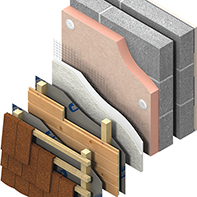

The office building was originally constructed in the 1980s and, whilst structurally sound, it did not meet modern office requirements and had limited re-use flexibility as internal floor configurations were designed specifically for a microelectronics company that previously occupied the building. Commercial Estates Group took the bold step to fully refurbish the building, upgrading it to net-zero operational carbon, adding an additional floor and completely reconfiguring internal spaces and the external façade.

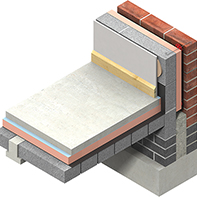

Working with a team of consultants, the architects developed a revised design, replacing the original façade to achieve a dramatic contemporary appearance externally, whilst providing modern office suites internally, along with a range of facilities such as café, gym, break-out area and additional amenity space. By retaining the existing structure, it was estimated that the project has saved some 1.7 million kg of embodied carbon. In order to reach net-zero operational carbon, a range of low-carbon technologies have been installed, including air source heat pumps and a PV array, and the architects looked to “reduce energy demand through fabric enhancement”. To support this approach, the OPTIM-R E Inverted Roofing System was specified for two large roof terraces.

Inverted Approach

The decision to adopt an inverted roofing approach reflected the roof terraces’ exposed position on the second floor at either end of the building. This could potentially mean that the surface has to handle considerable driving wind and rain, along with frost-thaw cycles. By situating the insulation above the membrane, it can provide an additional level of protection, helping to extend the membrane’s lifespan and safeguard against leaks.

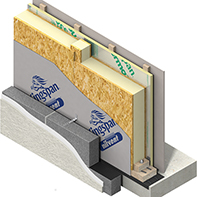

However, achieving this inverted approach would have been challenging with standard rigid extruded polystyrene (XPS) insulation, as a considerable thickness would have been required to achieve the target U-value. This may have meant creating a step-up out onto the terrace to accommodate the insulation depth. OPTIM-R E provided a clear solution. The system features vacuum insulation panels (VIPs) with a thermal conductivity as low as 0.008 W/mK, and a design thermal conductivity as low as 0.009 W/mK. This allows U-values to be achieved with slimmer thicknesses than would be possible with lower performing solutions.

The OPTIM-R E VIPs are encapsulated in a coating for increased robustness and easier handling on-site. The VIPs are accompanied by XPS insulation infill panels which can be cut to fit around features such as roof lights or ventilator kerbs. To support a swift on-site installation whilst keeping the depth of the insulation to a minimum, a clear system layout was created. This allowed the best possible ratio of encapsulated VIPs to infill panels. The site team fitted the OPTIM-R E System with a slim overlay of Kingspan GreenGuard GG300 insulation.

Zero operational carbon office

| T | (01544) 388 601 |

|---|---|

| 01544 387 382 Tech Dept. | |

| F | (01544) 388 888 |

| E | info@kingspaninsulation.co.uk |

| W | Visit Kingspan Insulation's website |

| Visit the Kingspan Insulation U Value Calculator | |

| Pembridge, Leominster, Herefordshire, HR6 9LA |