Class A Rated Substructures

Wallbarn

Wallbarn has a range of substructures and rail systems:

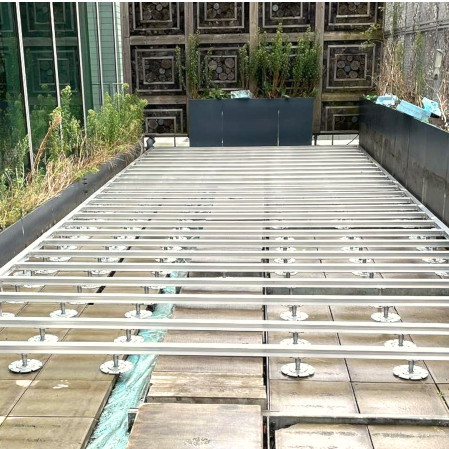

Class A Rail Substructure System

Aluminium joist/rail and pedestal substructure for non-combustible decking and tiling systems. Ideal for fire rated retrofit projects as part of the fire safety refurbishment requirement.

Key Advantages

• Class A rated (EN 13501-1:2018), fully compliant with BS 8579 and Approved Doc B.

• Full metal substructure, zero plastic and zero rubber “gaskets”, ensuring you will meet specification.

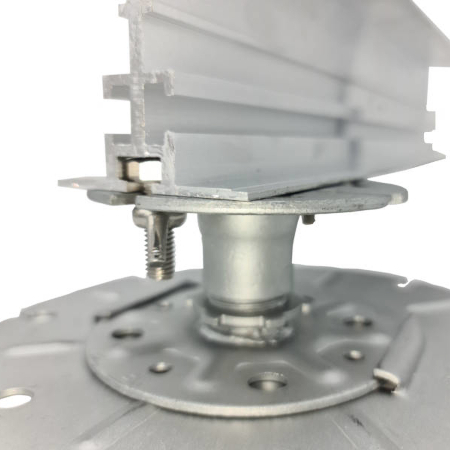

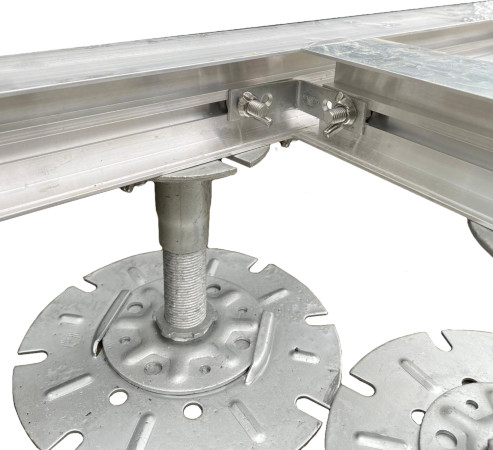

• Specially profiled bearer rails / joists are fitted to MetalPad EX pedestals via a wing nut and bolt fixing to the headpiece of the pedestal.

• Greater flexibility with installation as the frame can be connected loosely using the wing nuts, finely adjusted and then the nuts tightened once exact levels have been confirmed.

• Greater spans between pedestals, leading to possible cost savings per m2.

• Extensive Substructure height range from ultra low (17mm), to over a metre.

• Multiple rail to rail build up possible using specially designed Rail to Rail headpiece for large height thresholds.

• Capable of ultra low height thresholds with substructure achieving as low as 17mm using the Ultra Low Joist Holder.

• Additional tile positioning with Paving Headpiece fitted to rails for paving applications.

• All fixings and connectors provided making a complete Class A substructure system.

• High weight tolerance and extremely stable.

•Spreader Plate available for use on base of pedestals to assist with weight distribution and point loading, when building onto vulnerable sub floors.

• No rotting, warping or rusting

• Designed for long-term performance with warranties

Rail system

Suspension system for laying porcelain tiles and decking

Key Advantages

• Creates lateral stability across deck by reducing movement.

• Multiple layouts, height thresholds and interfaces available for whole manner of specific challenges when dealing with retrofit and refurbishment projects.

• Bespoke headpiece clips onto profiled aluminium joist.

Ultra Low Joist Holder

Ideal for projects requiring a Class A fire rating, this substructure is especially well-suited for retrofit and refurbishment projects where the height threshold for a paving or decking system is particularly low. The system includes our Class A Joist Holders, which are compatible with any of Wallbarn's aluminium rails/joists.

Key Advantages

• Achieve a total Class A Substructure from as low as 17mm.

• Particularly ideal for low height thresholds which have become common on retro-fit and refurb projects.

• Can be used for paving or decking projects.

Aluminium Box Rail

• Made from premium-grade 6063 T6 extruded aluminium.

• Originally conceived as an ultra- low height alternative to timber and composite joist/rails, it has now become a standard choice due to its lightweight and easy installation properties.

• Rails connect to MetalPad EX via wing nut and bolt connection.

• Height ranges available are 15mm, 20mm & 25mm and can be used with I-Plus Beams to build large height thresholds using the Rail to Rail headpiece.

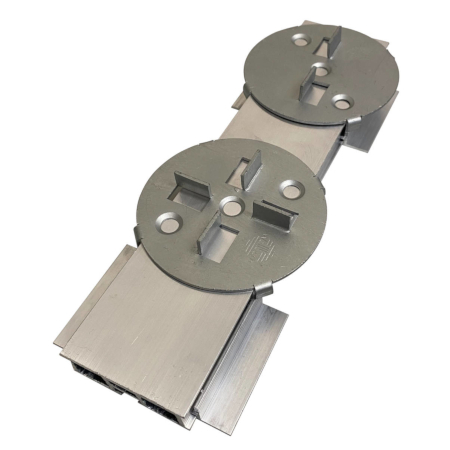

Connecting Box Rails

Connect Box Rails to each other along the straight plane or at right angles with specially designed connector plates / brackets for a mechanical fixing using self-tapping stainless steel screws. This creates a single platform level across the area which is sturdy and firm and ready to support the decking or tiling upper surface securely.

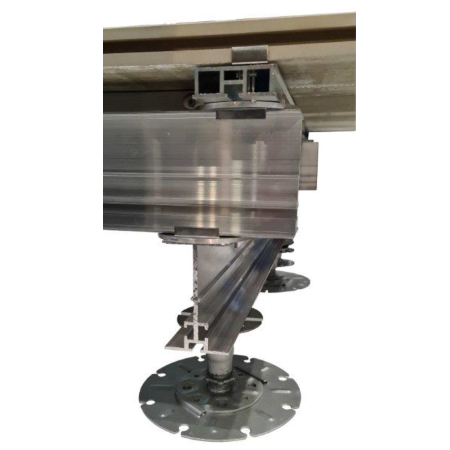

I-Plus Beam

Wallbarn’s I-Plus is an advanced aluminium rail/joist that establishes a new benchmark in substructure systems.

• The I-Plus Beam is available in three distinct heights: 50mm, 75mm and 100mm.

• Designed to be fitted to MetalPad EX pedestals through a wing nut and bolt fixing, creating a seamless, integrated and comprehensive substructure system.

• Fast, easy, seamless connection.

• Greater flexibility with installation as the frame can be connected loosely using the wing nuts, finely adjusted and then the nuts tightened once exact levels have been confirmed.

• Greater spans between pedestals possible leading to cost savings per m2.

• Strong and load bearing.

Connecting I-Plus Beams

For connecting I-Plus Beams, two convenient options are available. The first method involves using self-tapping screws for a sturdy mechanical fix. Both straight and right-angle fixing brackets feature two counter-sunk holes, facilitating straightforward attachment with the self-tapping screws.

The alternative connection option uses the Wing Nut & Bolt Kit, fitting through box sections extruded on each side of the I-Plus Beam. This allows rails to be hand-connected using the wing nut, enabling the beam platform to be loosely assembled. This arrangement permits minor adjustments in position or height before the entire system is tightened, securing a stable support platform for the decking or tiled surface above.

Using Wallbarn's Aluminium Joists / Rails on existing Steel Substructure

Wallbarn's Aluminium Rails / Joists are designed for extensive spans with minimal deflection, ensuring a strong foundation for your project. The Rail Headpiece can be attached to an existing steel substructure, accommodating any of our rails/joists.

For further assistance, please contact the Wallbarn Technical Team.

CROP227.jpg)