Overview

The project addressed waterproofing and ground gas protection after hydrocarbons were found during site investigations, indicating a potential risk.

Geological reports offer essential information for construction and resource extraction. They range from detailed site investigations to broader geological assessments. Site investigations help determine ground conditions, assess risk and guide planning decisions. Water table information is often provided, there are three water table grades: high, low, and variable. All designs should assume water will affect the structure at some point during the structure’s life cycle.

The geology of the ground, in addition to water tables, plays a crucial role in determining the type and specifications of a structure. Ground gas site investigations are key to identifying and mitigating risks from gases that accumulate underground and may enter buildings. These investigations are often required for planning applications, especially on brownfield sites or areas with known ground gas sources. The main reasons for conducting these investigations include ensuring public safety, complying with planning regulations, protecting property and infrastructure, and fulfilling environmental responsibilities.

Using multiple British Standards in design and specification ensures quality, safety and efficiency, streamlining processes and reducing risks.

BS 8485:2015+A1:2019 provides guidelines for designing protective measures against methane and carbon dioxide ground gases in new buildings and outlines strategies for creating specifications that ensure ground gas protection. With BS 8102:2022 'Protection of Below Ground Structures Against Water Ingress' is a code of practice providing recommendations and guidance for safeguarding underground structures from water penetration.

Delta Registered Installers, Advance Property Preservation Ltd were appointed to join the design team as Waterproofing Design Specialists, for the design and installation of a suitable ground gas protection and waterproofing system.

Methodology

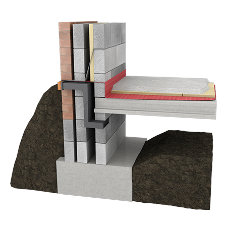

After site inspections, a strategy that addresses waterproofing and ground gas protection using a combined approach was proposed. This strategy included a full review of site inspection reports, structural drawings, and Building Control requirements.

A combined approach using the right waterproofing and gas protection design philosophy links systems and installation methods effectively.

The project was split into two phases:

Phase 1 – installation of a primary waterproofing solution and ground gas protection system.

Phase 2 – installation of a “combined” waterproofing system.

Phase 1

Prior to installation of the ground gas protection system, Koster NB 1, a high-performance migratory slurry (barrier protection system) and its system components were used on internal walls and the structural slab to prevent groundwater ingress, as a primary waterproofing solution.

Pro Liquid Gas Barrier (“LGB”) is a multi-use synthetic rubber-based gas protection and waterproofing system. Pro LGB offers a simple, continuous passive gas prevention barrier against the ingress of methane, carbon dioxide, radon, ground gas, VOC, air and moisture into buildings (hydrocarbon vapour suppression). Pro LGB also acts as a waterproofing membrane complying with the requirement C2 and C4 schedule 1 of the Building Regulations 1991 for England and Wales.

The Pro LGB, was spray applied with three coats in total for optimal coverage and protection.

During Phase 1, the continuity of waterproofing and gas barriers were seamlessly integrated, with all details thoroughly addressed.

Once the initial primary waterproofing system and ground gas protection systems had been incorporated into the project, independent third-party verifiers tested the ground gas protection system to ensure characteristic scores within BS 8485:2015+A1:2019 were met.

Gas System Verification is essential for safety, compliance, and proper function. It helps detect hazards such as gas leaks, carbon monoxide poisoning, and explosions, preventing serious outcomes, including fatalities. Verification ensures correct installation and adherence to safety standards.

This project passed and was verified in accordance with CIRIA 735 and installed to BS8485:2015+2019.

Phase 2

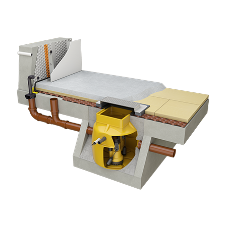

Following verification, Delta AT 800 membrane was incorporated into the design. Delta AT 800 not only provides a suitable Type C drainage system but also provides an effective gas barrier in accordance with Table 7 BS 8485:2015+A1:2019 and achieves less than 40ml/m2/day/atm in accordance with ISO 150501-1 Methane permeability test (Manometric method). All joints on the membrane were double sealed.

Products used:

• Delta AT 800

• Koster NB1

• Pro Liquid Gas Barrier (LGB)

Case Study Results

This project was delivered on time and within budget.

Advance Property Preservation Ltd supplied their client with a dry living space that is fully protected against water, damp ingress, and ground gas contamination ensuring reliable and cost-effective results.

Combination Waterproofing/Ground Gas Protection

| T | (01992) 523523 |

|---|---|

| F | (01992) 523250 |

| E | info@deltamembranes.com |

| W | Visit Delta Membrane Systems's website |

| DELTA House, Merlin Way, North Weald, Epping, Essex, CM16 6HR |

Products by this Company

227.png)