It has been another winter where the physical and emotional impact of severe flooding has yet again made the headlines, and those directly affected by the record-breaking rainfalls are now facing the long task ahead of them – refurbishment.

Delta Membrane Systems has, in recent years, supplied products more usually associated with tanking work in basements and the like for the refurbishment of flood-damaged properties.

The drying-out process often means that householders can remain in temporary accommodation for months, even years. However, Delta Membranes has pioneered a method of reinstatement that dramatically reduces the time families must endure with the disruption to their lives by eliminating the need for traditional drying with resultant cost saving to their insurers.

Already successfully employed in Hull, the Delta solution is to create waterproof boxes within the previously flooded rooms.

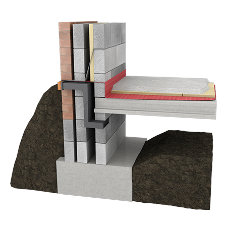

Delta’s PT cavity membrane can be fixed to a damp wall, and be dot and dabbed, and skimmed, in a fraction of the drying time demanded by traditional methods of remediation. The HDPE cavity membrane ensures air can circulate behind it, picking up residual moisture from the structure over the coming months without affecting the new finishes.

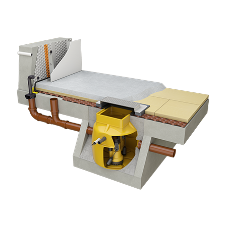

The same result can be achieved on floors, using the Delta FM membrane. It can be loosely laid over wet concrete floors and have a new floating floor system installed directly onto it. The 3mm air space created by the membrane again provides the physical separation for the new finishes and allows slow drying without significantly reducing head room.

This entire remedial process can be started soon after the flood waters have subsided, bringing a speedy and effective method of returning occupants into their homes.

View Basement Waterproofing Membranes Product Entry

227.png)