Helping Hand Brackets

RJ Facade Systems

RJ Facades offers innovative, engineered helping hand brackets for a wide range of façade systems. UL (Winmark, UKAS accreditation) approved facade systems, approval recognised by the NHBC.

→ Bracket and profile configuration is specified by RJ Facades technical department. To submit your project specifics please go to Facade Designer.

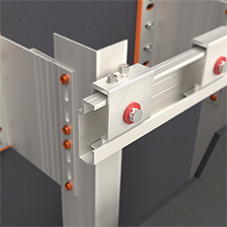

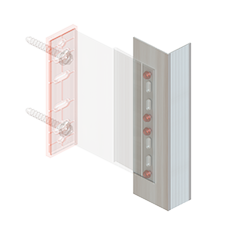

EVT II L-Brackets Aluminium

Designed as a single component without the need for an additional clasp, the extruded L-brackets have a one piece clip to hold main vertical profiles.

• UL (Winmark, UKAS accreditation) approved facade systems, approval recognised by the NHBC.

• Due to the brackets special designed shape being extruded, this allows the bracket to give additional reinforcement in critical areas while taking some of the additional weight away from other areas, assisting in the overall cost of the brackets.

• Aluminium brackets for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Part 1.

• Typical bracket configuration uses the Fixed Point bracket at the highest position on the vertical rail to support the façade vertical dead loads. The Sliding Point bracket is typically used on all other positions of the vertical rail to absorb the project wind loading.

• The brackets base has fixing slots suitable for concrete, steel and timber, it also includes slots and holes for Fixed and Sliding Point brackets.

EVT II L-Brackets Stainless

Stainless steel solution primarily to improve bracket thermal performance, corrosion and strength when supporting cladding materials.

• Designed using stainless steel for use where specification requires resistance to localised corrosion due to nature of building and/or local environment. Available in both Stainless steel 304 (A2) and 316 (A4) subject to specification requirements.

• UL (Winmark, UKAS accreditation) approved facade systems, approval recognised by the NHBC.

• The EVT stainless steel brackets have a superior thermal performance due to the low thermal conductivity of stainless steel. Often used to improve the overall U-value of a façade build up, which in some instances can lead to a reduction in the thickness of insulation.

• EVT Stainless L-brackets have a better design resistance than the standard EVT L-brackets and can be used where projects require higher loads acting on the substructure.

• Stainless steel subframe bracket systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 3 – Part 1.

• Typical bracket configuration uses the Fixed Point bracket at the highest position on the vertical rail to support the façade vertical dead loads. The Sliding Point bracket is typically used on all other positions of the vertical rail to absorb the project wind loading.

• The brackets base has fixing slots suitable for concrete, steel and timber, it also includes slots and holes for Fixed and Sliding Point brackets.

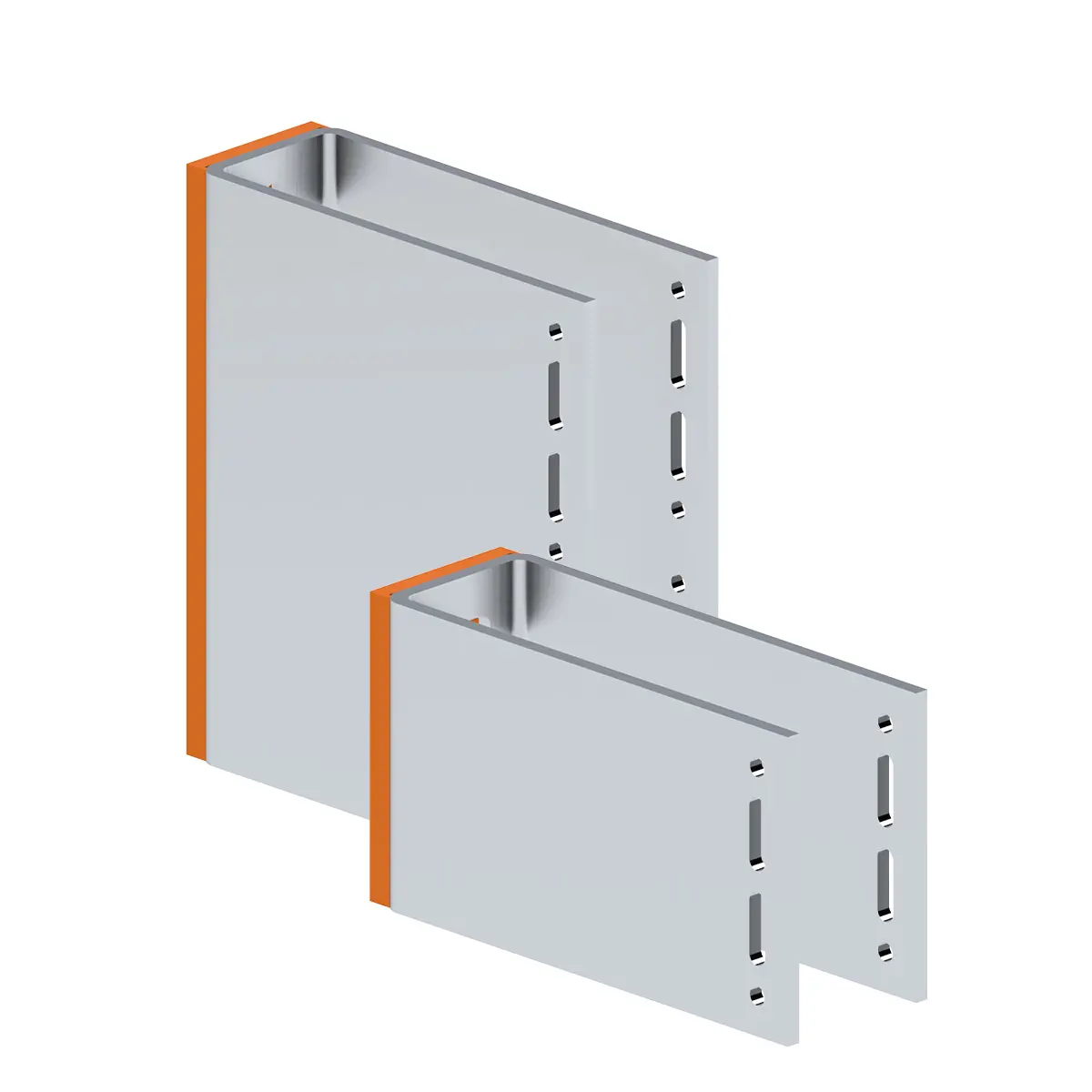

EVT II U-Brackets Aluminium

U-Shaped Brackets are designed to be capable of withstanding larger spans, engineered to support large cavities and where there is a need to span between floors due to fixing constraints between slabs.

• UL (Winmark, UKAS accreditation) approved facade systems, approval recognised by the NHBC.

• Subject to design approval U-Brackets can also be used to support medium to heavyweight facades in applications where the loadings are too high for standard EVT L-Brackets.

• Aluminium brackets for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Part 1.

• EVT U-Brackets are designed using vertical box sections with a 50mm base and varying depths, box section to be specified by RJ facades technical department.

• The brackets base has fixing slots suitable for concrete, steel and timber, it also includes slots and holes for Fixed and Sliding Point brackets.

EVT II U-Brackets Stainless

U-Shaped Brackets are designed to be capable of withstanding larger spans, engineered to support large cavities and where there is a need to span between floors due to fixing constraints between slabs.

• UL (Winmark, UKAS accreditation) approved facade systems, approval recognised by the NHBC.

• Subject to design approval U-Brackets can also be used to support medium to heavyweight facades in applications where the loadings are too high for standard EVT L-Brackets.

• Designed using stainless steel for use where specification requires resistance to localised corrosion due to nature of building and/or local environment. Available in both Stainless steel 304 (A2) and 316 (A4) subject to specification requirements.

• The EVT stainless steel brackets have a superior thermal performance due to the low thermal conductivity of stainless steel. Often used to improve the overall U-value of a façade build up, which in some instances can lead to a reduction in the thickness of insulation.

• Stainless steel subframe bracket systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 3 – Part 1.

• EVT Stainless U-Brackets are designed using vertical box sections with a 50mm base and varying depths, box section to be specified by RJ facades technical department.

• The brackets base has fixing slots suitable for concrete, steel and timber, it also includes slots and holes for Fixed and Sliding Point brackets.

www.amaresearch.co.ukEVT II Horizontal Adaptor

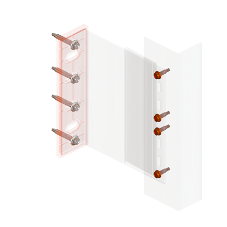

EVT II Horizontal Adaptors brackets are designed in a vertical direction to enable simple fixing to the SFS stud.

• UL (Winmark, UKAS accreditation) approved facade systems, approval recognised by the NHBC.

• The adaptor piece is designed to be fixed to a single EVT II bracket, for simple conversion of the support profile from vertical to horizontal position. Horizontal brackets are the best solution for to support T and L profiles in the horizontal plain for vertical plank systems and feature band details.

• The adaptor uses the features of the EVT II bracket range for multi-substrate application.

EVT II Soffit Brackets Aluminium

Designed as a single component, the extruded L-brackets have slots for fixing brackets to concrete, and holes for assembling the aluminium components.

• The brackets are constructed out of 2mm or 3mm extruded aluminium, this allows the design to be tailored to the building substrate and the panel characteristics.

• Aluminium brackets for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Part 1.

• Typical bracket configuration uses the single bracket version in 3mm aluminium thickness in all positions vertical rail to support the façade.

• The brackets base has fixing slots suitable for concrete, it also includes holes for simple connection to the L profile used to create the cavity zone.

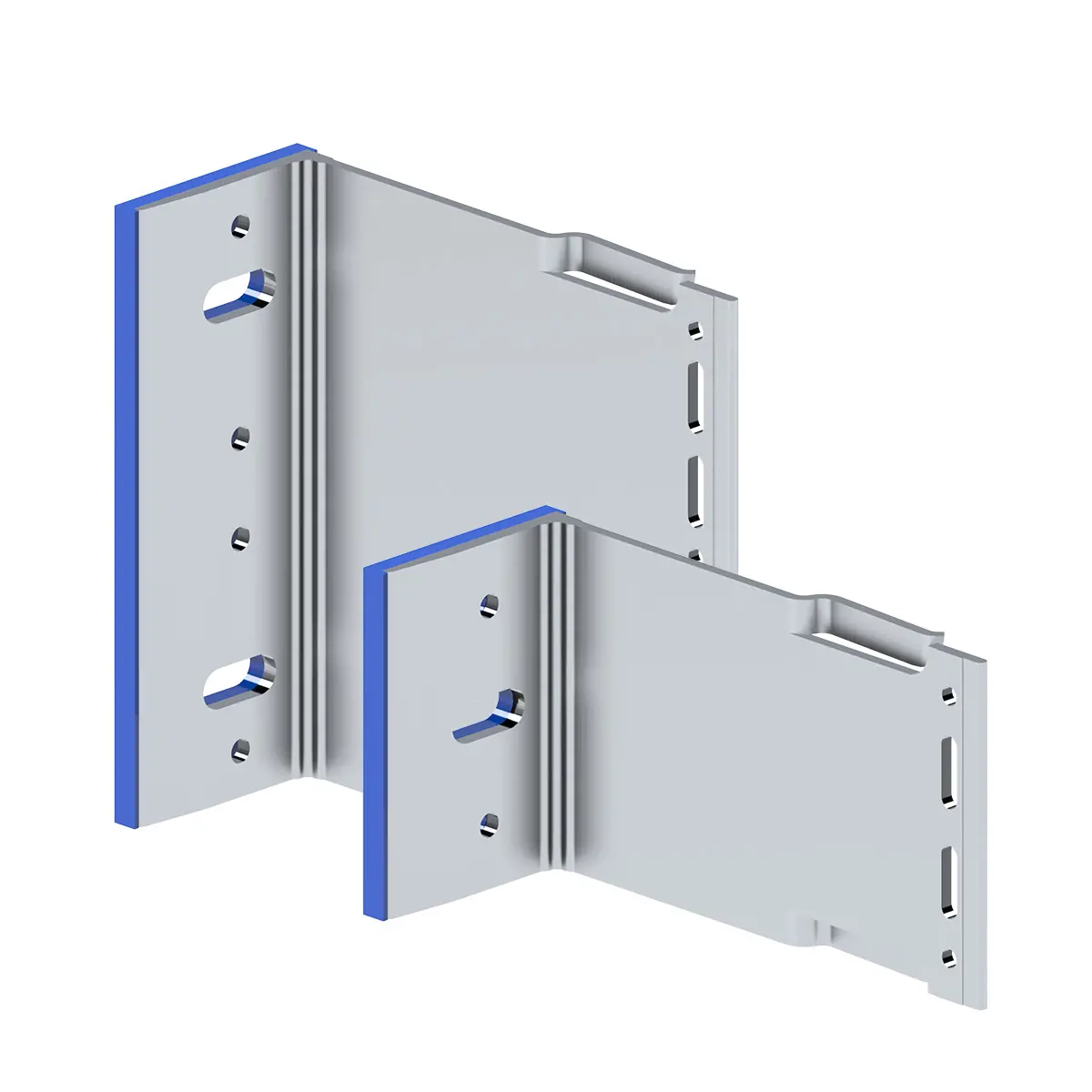

EVT L-Brackets Aluminium

Designed as a single component without the need for an additional clasp, the extruded L-brackets have "clips" punched into the brackets to hold main vertical profiles.

• Due to the brackets special designed shape being extruded, this allows the bracket to give additional reinforcement in critical areas while taking some of the additional weight away from other areas, assisting in the overall cost of the brackets.

• Aluminium brackets for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Part 1.

• Typical bracket configuration uses the Fixed Point bracket at the highest position on the vertical rail to support the façade vertical dead loads. The Sliding Point bracket is typically used on all other positions of the vertical rail to absorb the project wind loading.

• The brackets base has fixing slots suitable for concrete, steel and timber, it also includes slots and holes for Fixed and Sliding Point brackets.

• Brackets are available with various thermal pad options to improve overall thermal performance.

%20-%20Fixings%201crop227.png)