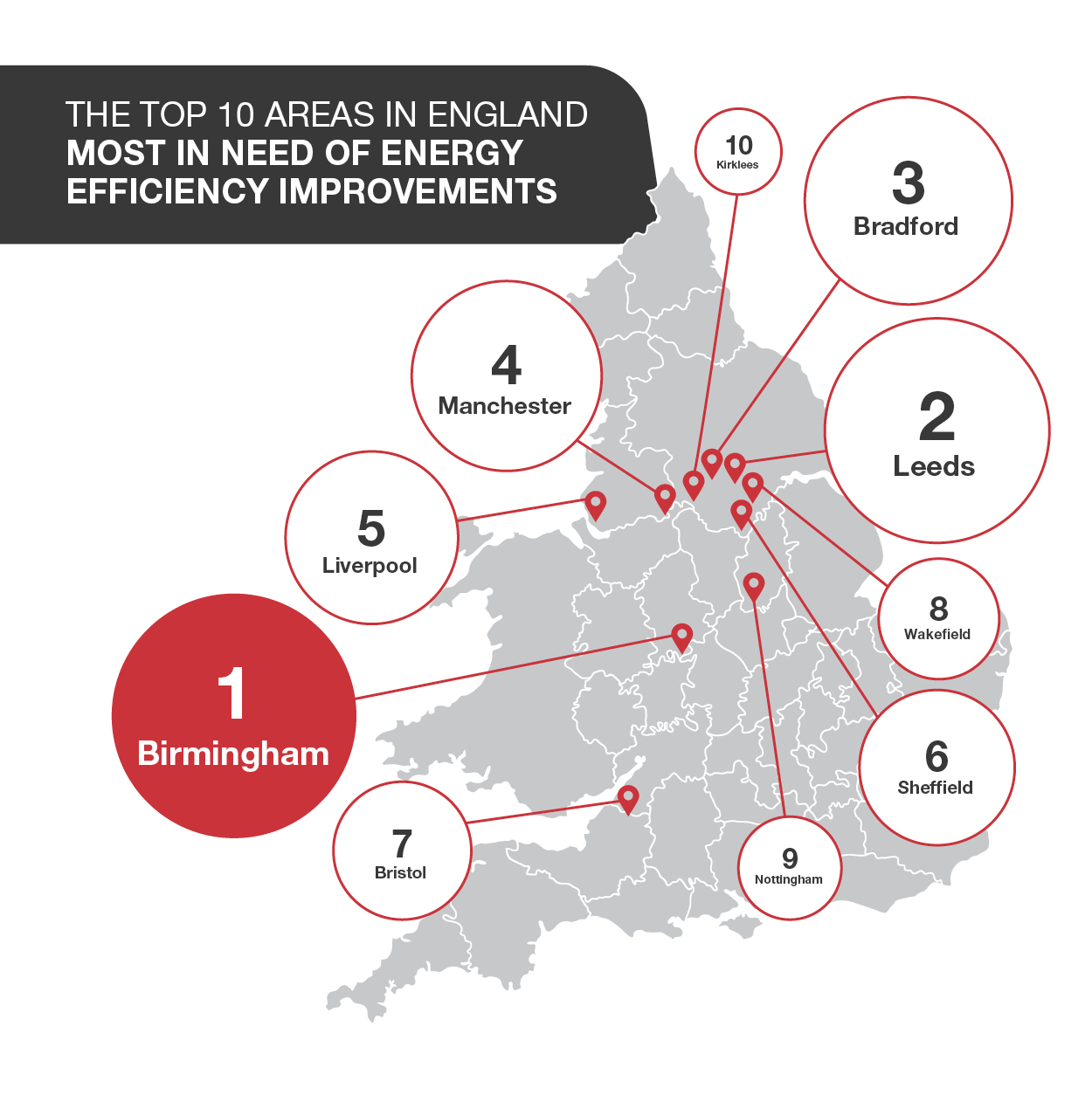

A new industry report commissioned by Eurocell has revealed a stark reality: England must retrofit one home every minute between now and 2050 to meet its national net zero commitments.

The independent research, conducted in partnership with Cicero/amo, explores how prepared the construction industry is to deliver energy-related upgrades across England’s 23 million existing homes. The conclusion? We’re falling short - and time is running out.

Key findings include:

• Over 19 million homes require energy-efficiency upgrades by 2050

• Just 4.2% of homes currently meet EPC Band C or above

• More than 50% of homes were built before 1980 - long before energy performance was a design priority

• Retrofitting must scale up by over 12 times the current rate to hit 2050 targets

These figures highlight the urgent need for high-performing, sustainable, and scalable retrofit solutions- particularly across social housing and ageing private stock.

Be Retrofit Ready with Eurocell

Eurocell’s Logik 70mm casement window system is engineered to meet the demands of energy-efficient retrofitting.

Logik System Highlights:

• Exceeds Part L requirements – Achieves U-values as low as 1.2 W/m²K

• Improves EPC ratings – Can help properties upgrade from Band D to Band C

• Multi-chambered profile enhances insulation and reduces heating costs

• Integrated trickle vents improve air quality and support compliance with Approved Document F

• Sustainable by design – 100% of removed PVC-U frames are recycled

• UK-manufactured, reducing transport-related emissions

Advanced Sustainability Through Design

Logik profiles feature over 40% post-consumer recycled PVC-U as standard. Using Dual Material Extrusion Technology (DMET), Logik combines recycled core material with a virgin outer layer - delivering performance and sustainability without compromising aesthetics. The recycled material is completely invisible in the finished product, making it ideal for refurbishment projects where appearance and compliance matter.

Carbon Footprint Reduction Backed by Research

To further substantiate the sustainability credentials of PVC-U product solutions, Eurocell worked with the Faculty of Science and Engineering at Manchester Metropolitan University to review an array of data sets and modelling emanating from peer-reviewed publications. This would establish a life cycle assessment of the use of recycled PVC-U in the company’s manufacturing operations.

Eurocell requested the scientists interrogate the set estimates for overall CO2 savings that can be achieved from the use of waste PVC-U and determine an accurate statistic to prove the environmental benefit of using waste PVC-U within recycling operations.

• Replacing one tonne of virgin PVC with recycled PVC can reduce CO₂ emissions by approximately 1.7 tonnes

• Using one tonne of post-consumer PVC-U saves up to 2.056 tonnes of CO₂ equivalent - roughly two months’ worth of emissions from the average UK resident

This reinforces the value of circular manufacturing in reducing the carbon footprint of retrofit projects at scale.

Read the full research report:

eurocell.co.uk/blog/one-every-minute-the-rate-homes-in-england-need-energy-related-upgrades-to-meet-2050-net-zero-target

Partner with Eurocell to retrofit better. Build smarter. And help close the gap - one home at a time.

For more information on how Eurocell can assist you in delivering your next project, please contact the team commercialsales.profiles@eurocell.co.uk.

One Every Minute: The Retrofit Rate Needed to Hit Net Zero by 2050

| T | 03301 737 159 |

|---|---|

| E | marketing@eurocell.co.uk |

| W | Visit Eurocell's website |

| Eurocell Head Office and Distribution Centre, High View Road, Alfreton, Derbyshire, DE55 2DT |

Categories

Transport Residential buildings Secondary glazing