Canrobert Street is a typical residential road in East London used by local residents for access and parking. The existing surface was aged and in need of replacement. Due to increased pressure for lower carbon construction a durable, cleaner solution was required that could also minimise disruption during installation.

The site was challenging because the street was narrow with a four-way speed table at the crossroads bisecting the road at the midpoint.

Tarmac proposed, in conjunction with Riney, to supply both binder and surface courses in Rubber Modified SMA designs.

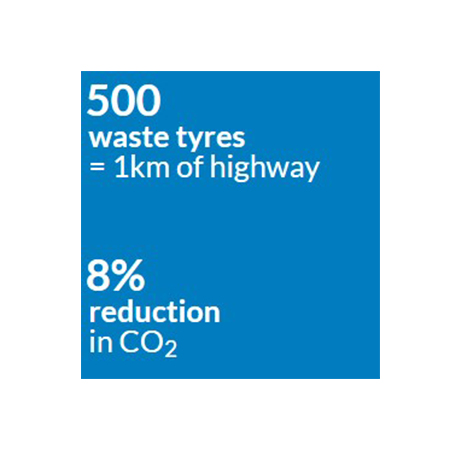

The stone on stone structure of SMA gives good resistance to rutting and deformation and the addition of recycled crumb rubber into the mix enables a bitumen rich design giving extended pavement life and a use for a previously problematic waste stream of old tyres.

Results and Benefits

All rubber modified asphalts are produced in warm mix which enabled the works to be completed to a shorter programme than conventional materials and offer CO₂ savings against hot mix equivalents.

Disruption was minimised due to the cooler material temperatures with the road reopened quicker than traditional SMA.

Additional information

Sustainablity

Rubber Modified Asphalt is just one of the many sustainable solutions from Tarmac. The development of Rubber Modified Asphalt is part of their commitment to the circular economy, with the business recycling 8.7 million tonnes of waste from other industries every year.

Lower carbon emissions

The typical carbon footprint of Tarmac’s rubber modified SMA solution will be around 8% lower than the equivalent.

Successful UK Trials

Rubber Modified Asphalt has been trialled and tested on roads in Coventry, Leicester and North Tyneside.

View Asphalts made with lower carbon emissions and higher recycled content Product Entry