In this blog written by Delta Membrane Systems Limited, Kevin Dodds, Director at Delta, explores the complexities and challenges on structural waterproofing projects which also require ground gas protection.

Waterproofing structures offers protection to structural components, buildings, and installations from the penetration of water; it reduces risk and will prolong the life time of the structure. However, some below ground construction projects require protection from both water ingress and gas contamination.

It’s now possible to produce a waterproofing design which incorporates both a waterproof and gas proof protection system, however these types of projects require a different strategy and methodology as to what would be classed as a typical waterproofing design.

Both BS8102:2009 and BS8485:20015 are intertwined. Basements and below ground structures which need to be watertight and gas proof are not anymore complex to design but require further considerations at the design phase and throughout the project.

The object of structural waterproofing is to protect a structure for its lifetime from water ingress.

The object of ground gas protection is to prevent a build-up of gasses against a structure.

When it all goes wrong...

Gorebridge, a town just south of Edinburgh hit the headlines, a Midlothian council developed a former mining area for 64 new homes. The council had taken all appropriate measures to ensure there would be no ground gas contamination in these homes. The council engaged with architects, principal engineers, contaminated land specialists, structural engineers and ground investigation engineers. What could go wrong? Seemingly there was no gas proof membrane incorporated in the floor slab construction….the reason - it wasn’t specified.

22 residents of the 64 homes complained of dry coughs, dizziness, headaches and anxiety. Six ended up in hospital and a £12m legal battle commenced - who was to blame for this error? The Gorebridge incident could be an exceptional event or ground gas contamination may be a more widespread issue yet to be detected.

Combining waterproofing design with ground gas protection:

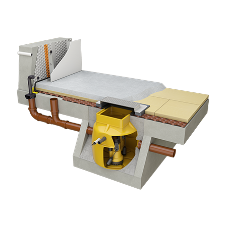

Innovations within the waterproofing sector have seen the introduction of Ground Gas Protection Systems, which are capable of offering both gas protection and waterproof solution.

A Waterproofing Design Specialist will be able to interpret the requirements of BS8102:2009 and BS8485:2015 to produce a waterproofing design which incorporates both a waterproof and gas proof protection system.

If a site has been identified with a gas or hydrocarbon contamination it will have been given a Characteristic Situation Score. The Characteristic Situation Score is defined according to how severe the gas flow from the ground is.

All sites which have been characterised with a gas situation score will require a gas protection system and where identified a waterproof protection barrier.

Methods of gas protection:

Gas protection is a technical solution to prevent or to control gas penetration into properties. The control of gas migration is normally achieved by blocking the pathway or removing the source of the gas generation. There are several methods available to achieve the protection to existing/new build properties.

Gas protection measures available to achieve the minimum points score requires a combination of two or more of the following protection measures be used:

• The Structural Barrier

• Ventilation Measures

• Gas Resistant Membrane

Methods of structural waterproofing

There are 3 Types of waterproofing methods. These are defined as:

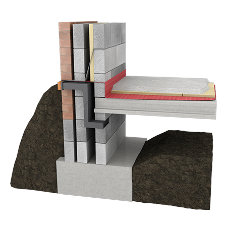

• Type A Tanked or Barrier Protection. Cementitious or bitumen-based products applied internally, externally or sandwiched

within the structure.

• Type B Structurally Integral Protection. Reinforced or prestressed concrete designed through composite and integrated details such as water bars to be water resistant.

• Type C Drained Protection. Cavity Drainage Systems which allow for water

ingress but in a c ontrolled fashion.

Evaluation of groundwater conditions, risk assessment and options for drainage outside the structure should always be considered.

The dangers of ground gases:

• Hydrocarbons

• Hydrocarbons derive from the petrol chemistry industry

View Ground Gas Protection Systems Product Entry

![The complexities and challenges on structural waterproofing [BLOG]](/blog2-file094407.jpg)

![The complexities and challenges on structural waterproofing [BLOG]](/blog3-file094408.jpg)

227.png)