Delta Membranes Systems Ltd have provided their cavity drain membrane system for damp-proofing at a property on Corona Road, installed by Anglia Property Preservation Ltd.

The project was to convert a former vehicle maintenance and repair workshop into a dwelling. The workshop was of a solid wall construction (brickwork), the roof had been removed and all internal walls were painted.

A cavity drain membrane system was chosen for the damp-proofing due to advantages over the cementitious coating systems on a property like this.

Old buildings are often built of masonry with lime mortar which may suffer small movement cracking over the years.

One of the main advantages of cavity drain membranes over cementitious systems is that they do not stop water at the point of entry, so hydrostatic pressure is not increased any more that it would be without a waterproofing system.

For this reason, it is often possible to retain substrates which would have to be replaced when using a cementitious system, and yet still comply with BS 8102:2009

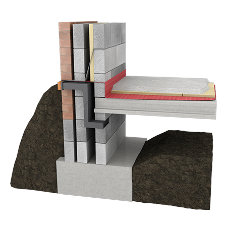

The Delta system is an extruded HDPE membrane with 8/20mm studs, which allows water vapour (dampness) to move in all directions across the whole of the wall and floor surfaces, achieving damp pressure equalisation.

The mortar joints were then raked out & repointed with Koster Repair Mortar Plus & SB Bonding Emulsion.

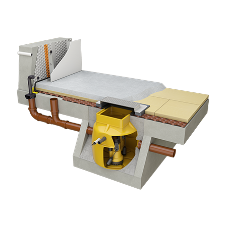

The original flooring was broken up and a new concrete floor laid to the architect’s specification with a channel formed along the side where the wall was earth retaining for the Delta drainage channel to be fitted in. A cavetto was formed at the wall/floor joint of all walls, using Koster Repair Mortar.

A Koster Polysil TG500 priming coat was applied over the new concrete slab to reduce the risk of excess free lime leaching out during the curing process followed by 2 coats of MemTech Pro LGB including into the drainage channel area, which was reinforced with MemTech Flexi Tape.

The application of MemTech Pro LGB was continued up the walls to a height of 1.5 metres.

MemTech LGB is a ready for use specialist styrene butadiene latex based liquid applied gas membrane. It offers continuous passive gas prevention barrier against the ingress of Methane, Carbon Dioxide, Radon, Ground Gas, VOC, air & moisture into buildings.

MemTech LGB complies with the latest codes of practice as published by BR211, CIRIA and BSI (BS 8485:2015+A1:2019).

Suitable for use as gas protection for NHBC GREEN, AMBER 1, and AMBER 2 site characterisations. Delta MS 500 membrane was applied to the wall surfaces with fixings use a sealed brick-plug using Koster PU 907 sealant.

The top edge of the membrane was sealed with sealing rope/tape, the Delta drainage channel was installed into the channel along the retaining wall side with a flushing point at the end of the run.

Delta MS20 (20mm stud) studded membrane was laid over the floor and sealed to the wall membrane.

View Ground Gas Protection Systems Product Entry

227.png)