Delta Membrane Systems Limited share their thoughts on Virgin and Recycled plastic, and which they think is best suited for the Waterproof Membrane industry:

Society today has an immense focus on sustainability and renewable resources making it hard to understand why any products are made from virgin material.

What is the difference between “virgin” and “recycled” plastics?

Virgin: is the direct resin produced from a petrochemical feedstock, such as natural gas or crude oil, which has never been used or processed before.

Recycled: Post-consumer is a material that has been reclaimed after it has left the hands of the consumer. For example, a

plastic milk container, detergent bottle or oil bottles, the plastic container is taken to a facility where it is washed, reground and pelletized into a new post-consumer material.

Post-Industrial, is recycled plastic that never left the manufacturing floor. For efficiency, manufacturers try to achieve zero

waste during the production process.

Which process is the cleanest for manufacturing waterproof membranes?

Neither post-consumer nor post-industrial recycled materials can achieve 100% of the mechanical properties of virgin materials. The quality of these recycled materials has a direct long-term life prediction (with some membranes made from recycled material only having a 5-year life prediction (according to EN 13252)).

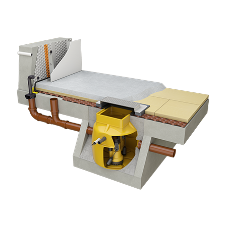

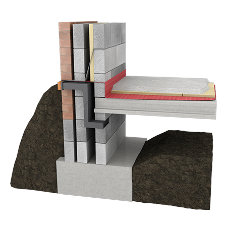

Delta MS 500, MS 20, P T and FM are made from virgin High-Density Polyethylene (HDPE), our tested service life is over 100 years!

The membranes made from recycled materials will also have a lower safety and strength rating.

Virgin HDPE membranes also offer a higher resistance to oxidation. The presence of virgin resin significantly improves the durability of dimpled membrane sheets with observed ratios in the range of 2 to 20 (depending on the tested materials).

Surprisingly, post-consumer is the least “clean” of the three methods listed above for manufacturing waterproof membranes, because of the variability of the feedstock.

Not to say, recycled plastics cannot be used in various other applications, but this does give an explanation as to why recycled materials have lower safety & strength ratings and life prediction.

It is tempting to believe that if something is recycled it is more sustainable than something made from virgin material. Sometimes this is true, but not in all cases.

Every manufacturer should manufacture products through economically-sound processes that minimize negative environmental impacts whilst conserving energy and natural resources.

Energy efficiency: Despite growing production volumes, we have achieved a steady efficiency coefficient:

Year MWh/d

2014 1,01

2015 0,96

2016 0,90

2017 0,90

View Basement Waterproofing Membranes Product Entry

227.png)