A blog written by Altecnic...

CIBSE's updated Code of Practice (CP1) 2020 is a document outlining the minimum standard for heat networks across the UK. The document sets the minimum requirement for best practice within the industry as it aims to improve the quality of heat networks.

Its recommendations also aim to improve overall energy efficiency and have a positive environmental impact.

What does this mean for heat networks?

The new document has a substantial impact on the district energy and heat network industry, paying particular attention to improving new build and existing heat networks by future proofing them and increasing efficiency.

CP1 (2020) has drawn focus on efficiency at low temperatures in response to the forecast for rapid increase in the dominance of heat pump technologies, therefore leading to the recommendation that heat networks should be specified and developed with low temperature energy sources in mind.

If this best practice is followed, Altecnic believe that this will have a positive impact on the efficiency and future proofing of heat networks. It also aligns with their commitment to contribute to a more environmentally conscious construction industry.

Altecnic continues to develop innovative products with efficiency in mind as well as to educate both their employees and customers on the accredited content provided by organisations like CIBSE.

How will Heat Interface Unit's (HIU) be impacted?

CP1 (2020) emphasises the importance of efficiency of heat interface units on low temperature heat networks and in particular, goes into detail on how HIU's should have a low primary flow rate.

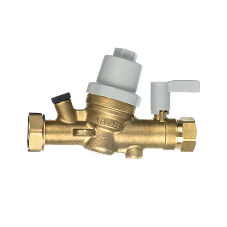

For example, the Altecnic SATK32107 is specifically designed for use on low temperature networks and operates efficiently at a significantly low primary flow temperature.

The guidance lays out clear objectives for heat interface unit manufacturers to meet, particularly as the industry standards such as the BESA test already allows specifiers and engineers to easily benchmark HIU performance at low temperature.

What other areas does CP1 (2020) suggest best practice?

Thermostatic Radiator Valve's (TRVs) play a key role in achieving the efficiency benefits of a hydraulically balanced system.

Due to this, CP1 (2020) states that pre-settable TRVs have become the minimum recommended standard of TRV to fitted in any heat network system, with a pressure independent TRV being best practice.

The pressure independent TRV is best practice as it ensures that the required flow rate is met by automatic balancing to all load conditions. Dynamic, pressure independent radiator valves, such as those in Caleffi 230 Series range offer this functionality, and are also available in low flow versions.

Overall, Altecnic believe that CP1 (2020) is a further step in the right direction for improving the overall quality, efficiency and sustainability of all heat networks in the UK.

If you have any questions about the SATK32107, or any other product mentioned in this blog, please contact: specificatons@altecnic.co.uk.

View SATK32 Indirect Heat Interface Unit Product Entry