Thermal structural connectors

Schöck

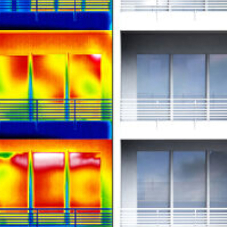

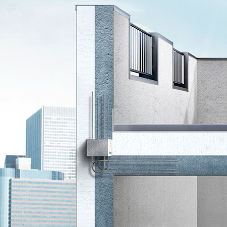

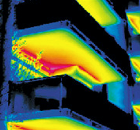

Thermal bridges are part of a building where heat and/or cold is transferred at a substantially higher rate then through the surrounding envelope area.

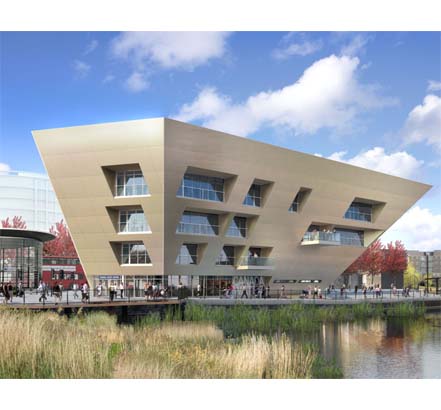

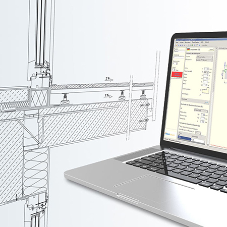

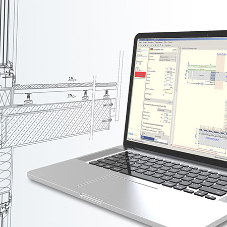

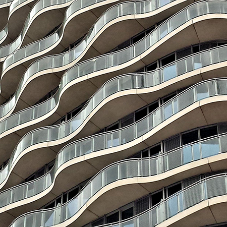

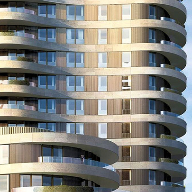

Using the latest generation of materials, coupled with innovative design and application, the Schöck Isokorb® range has helped set the benchmark in thermal break and thermal bridging technology.

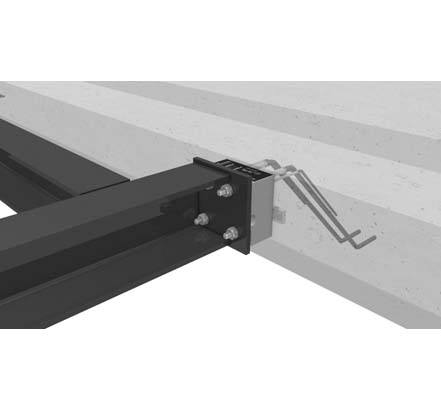

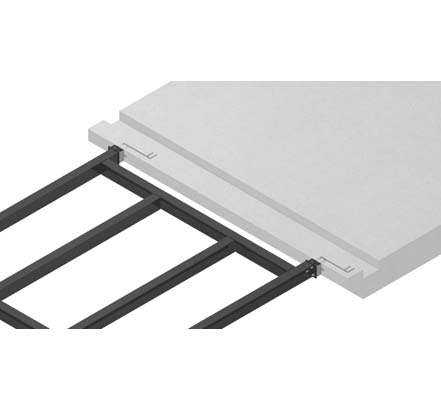

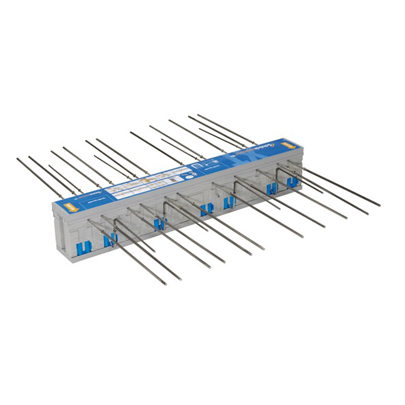

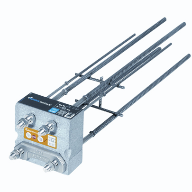

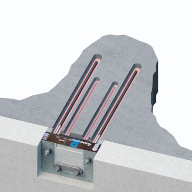

The Isokorb® range offers three types of structural connection; concrete-to-concrete, concrete-to-steel and steel-to-steel. All provide fully independent and verifiable thermal performance data.

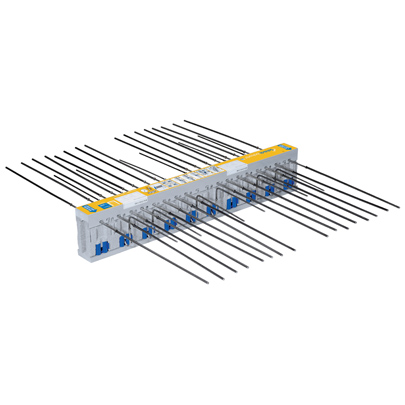

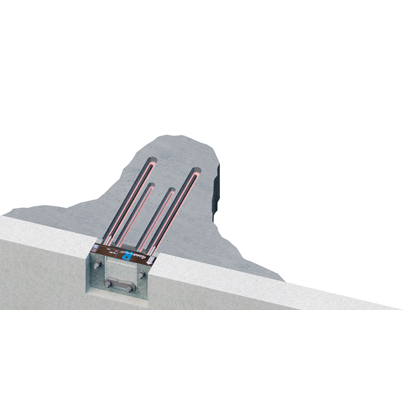

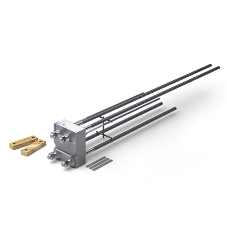

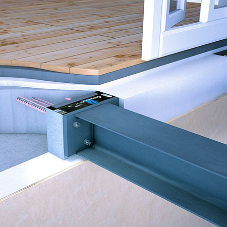

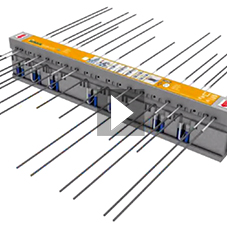

The Isokorb® product range consists of loadbearing thermal insulation elements that form a thermal break between the balcony, or other structural cantilever parts, and the internal floor, whilst transferring load and maintaining structural integrity.

The Schöck Isokorb® type K, with HTE-pressure-bearing module, provides the best thermal performance achievable with thermal breaks. It also offers a unique degree of stability and versatility. This new generation of Isokorb® provides optimum structural solutions and proves to be an attractive option for the stringent demands of thermal efficiency in energy-saving construction, thus ensuring compliance with Part L. The Isokorb® range comfortably exceeds the requirements of the UK regulation (BRE IP1/06) which stipulates that the temperature factor used to indicate condensation risk (fRSI), must be greater than, or equal to, 0.75 for dwellings, residential buildings and public buildings.

Also, there is compliance with the Government Standard Assessment Procedure, SAP 2009, concerning CO2 emissions from buildings and respectively heat losses through non-repeating thermal bridges. Here, the lambda values of the Schöck Isokorb® enable energy loss in various connective situations to be reduced by as much as 84% to 91%. All products provide BBA Certification and LABC Registration.

resized-comp212922.jpg)